Chocolate

Our equipment suits your sweet applications best

- Hygienic design

- Melting, crystallizing, mixing, blending and buffering

- Inhouse product and process knowledge

- We have test our own test facility or mobile test equipment

Previous

Next

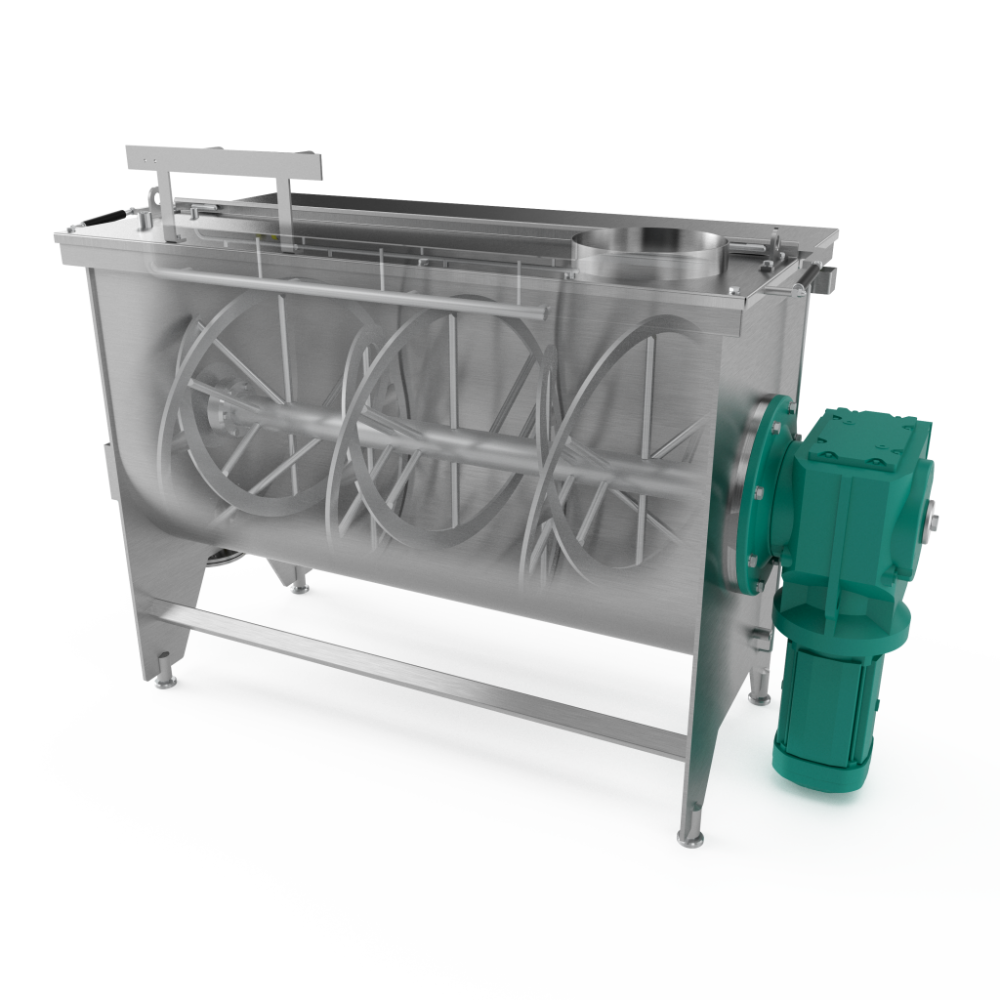

Production of good quality chocolate product demands a very specific production process. Gpi designs and manufactures tanks and equipment which are special for the chocolate industry.

With chocolate, it’s very important that the melting process is controlled very precisely. Our tanks can be equipped with a double jacket, or even multiple jackets, to control the melting process.

When cooling down chocolate, you want to have a certain level of crystallization. By applying a cooling medium on the wall, you can have controlled crystallization.

For both heating and cooling or crystallizing, you want to have a homogeneous mixture of chocolate. Therefor we use inhouse designed and manufactured agitators with scrapers. This way no product will crystallize or burn on the surface and the product stays homogeneous.

Storage tanks, heat exchangers, buffertanks, melting units and process tanks. Gpi has years of experience in the chocolate industry, and has grown to become a specialist in the various aspects within the chocolate industry. As a result, we are able to give the best advice on heating in for example a chocolate melting unit or cooling in a Scraped Surface Heat Exchanger (Kelstream) and on the correct finish, and can guarantee you a product with a long lifespan. In addition, we design and manufacture our own agitators to guarantee the perfect tank-agitator combination.

© Gpi De Gouwe 2024