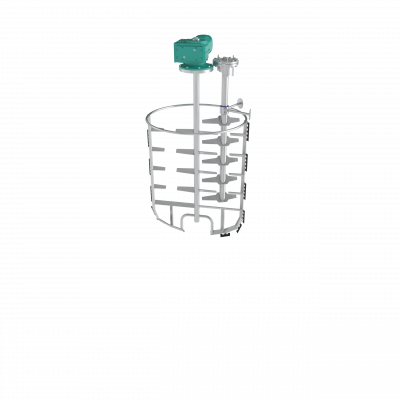

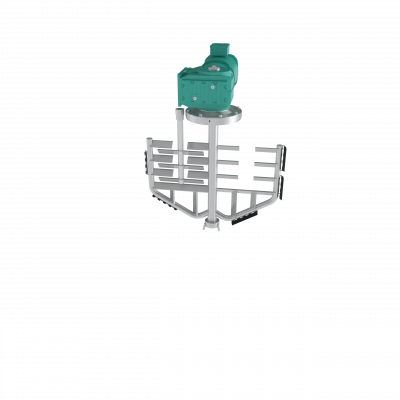

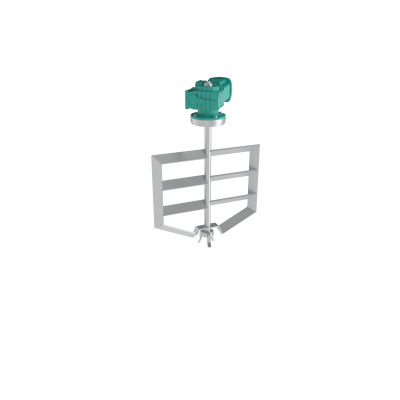

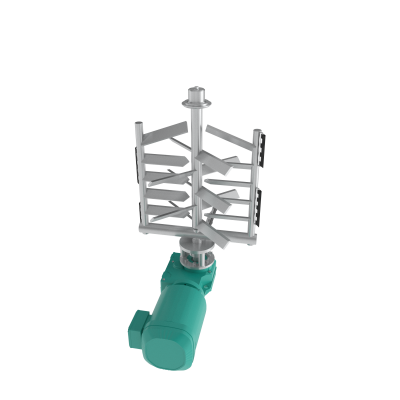

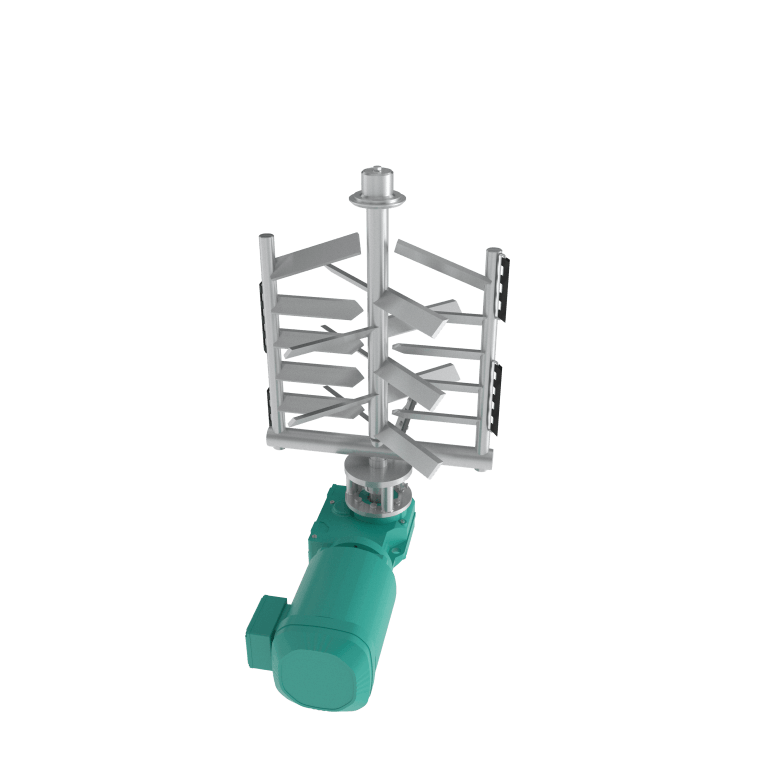

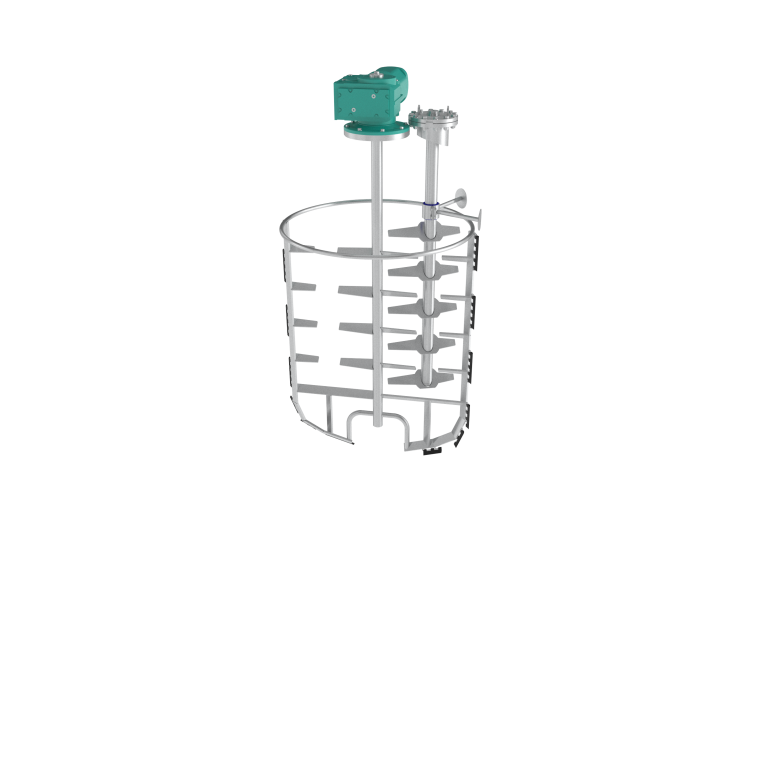

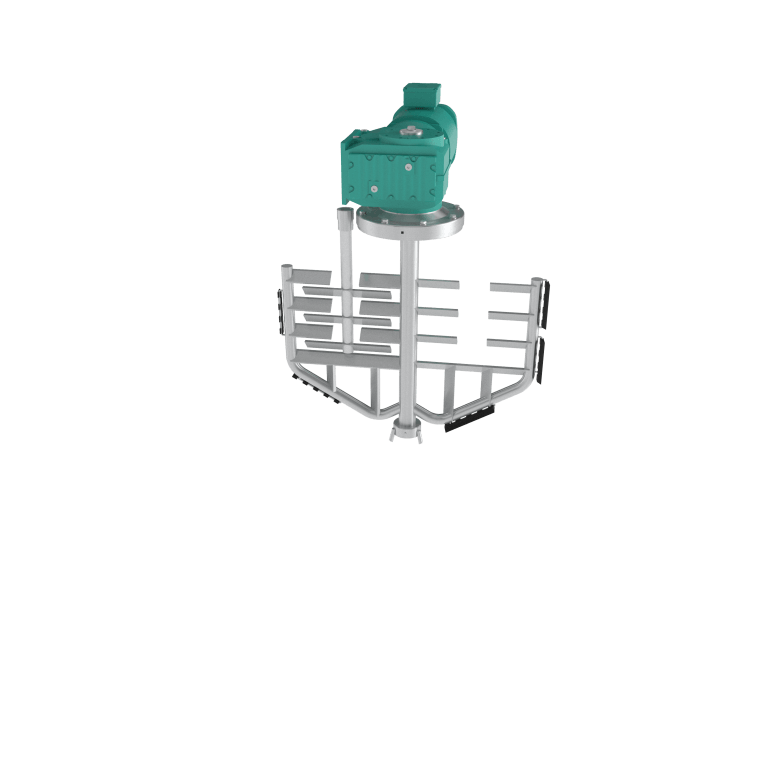

Agitator

Inhouse designed and manufactured stainless steel agitators

- Hygienic design agitators

- Used in food, pharma and cosmetics

- Perfect tank-agitator combination

- Possible with scrapers, stators and other options

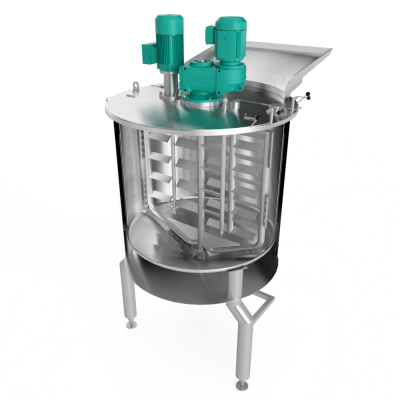

Stainless steel tank with agitator

Agitators come in various sizes and can be used in a wide range of industries. Gpi Process Equipment is a manufacturer of stainless steel tanks, but also manufactures agitators, designed to fit your products and processes.

Agitators should serve your product, don’t damage it and give you the desired end product.

Options and applications

- Mixing

- Keeping Homogeneous

- Emulsifying

- Crystallizing

- Dissolving

- Suspending

- Dispersing

- Deaerating

- Improve heat transfer

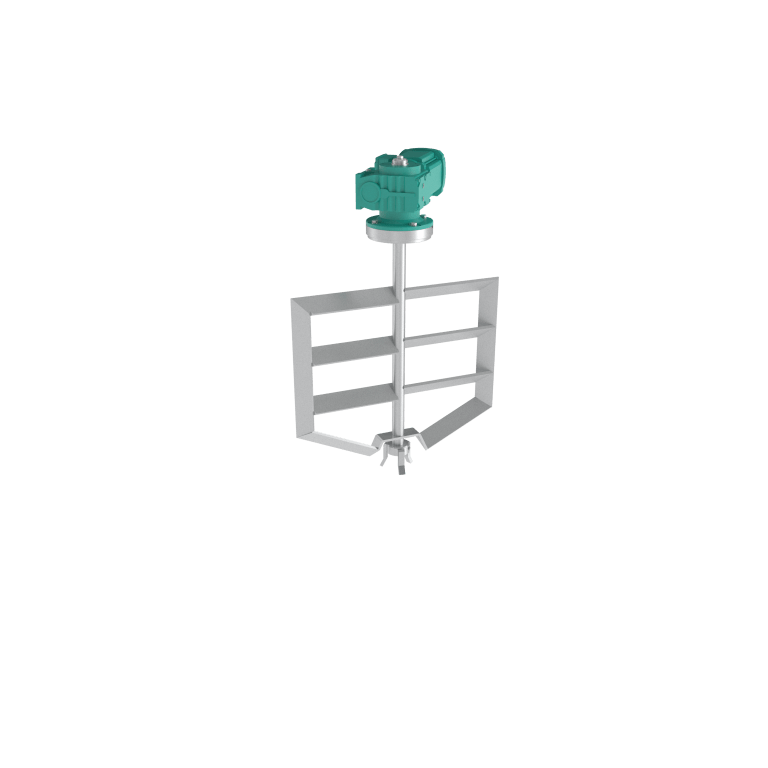

- Gate agitator

- Anchor agitator

- Scraping agitator

- Propeller agitator

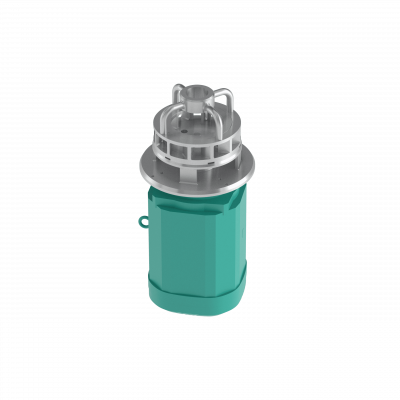

- Bottom driven agitator

- Dispersing disk

- Rotor/stator

- Screw agitator

- Combination of agitators

- High shear mixer

- Turbo mixer

- Side entry agitator

- Static mixer

- External homogenizer

Soups and sauces | Fruit | Food | ||

Tomato sauces | Fruitfilling | Mashed potato | ||

Sauces | Piefilling | Mechanically Deboned Meat | ||

Dressings | Fruitpuree | Ready-to-eat fillings | ||

Salsa | Jam | Egg | ||

Hummus | Marmelade | Jelly | ||

Soup | Fruitsauce | Peanut Butter | ||

Starch slurry | Applepulp | Pharma | ||

Spreads | Dairy | Lotions | ||

Confectionary | Milkconcentrate | Creams | ||

Fat cream | Cheese sauce | Wax | ||

Chocolate | Yoghurt | Toothpaste | ||

Caramel |

The agitator serves your product

We understand that an agitator should serve the product. Therefor we design our agitators tailormade for you, so you can be sure that the agitator and tank will suit to your product and process best. Agitators we can help you with:

- Gate agitator

- Anchor agitator

- Scraping agitator

- Propeller agitator

- Bottom driven agitator

- Dispersing disk

- Rotor/stator

- Screw agitator

- Combination of agitators

- High shear mixer

- Turbo mixer

- Side entry agitator

- Static mixer

- External homogenizer

Finishing levels

As a standard, Gpi ensures a high-finishing level. For some applications, such as in the food industry or even in the pharmaceutical industry, specific requirements are applicable. As a standard, our agitators are produced with an surface roughness of Ra 0.8, but if desired we can also produce agitators with much smoother (and therefore more hygienic) surfaces.

Mixing Tank

Standard or tailor made stainless steel mixing tanks. Perfect for your product and process.

- Efficient mixing, blending and homogenizing

- Inhouse design and manufacturing of agitators

- Both manual as CIP cleaning possible

- Various options available for optimal integration on your product and proces

Stainless steel mixing tank with agitator

Mixing tanks come in various sizes and can be used in a wide range of industries. Gpi Process Equipment is a manufacturer of stainless steel mixing tanks designed to fit your products and processes. Our mixing tanks start as small as 50 liter but can go up to 10.000 liter or even bigger.

For processes such as mixing, blending, keeping it homogenious, an efficient agitator or a combination of agitators is necessary. Let us know what you would like to achieve, and we will collaborate with you in order to arrive at the most efficient solution.

“Gpi has a great deal of knowledge in house, they are a flexible company, they know a great deal about production processes and operations and they really listen to their clients“

Harco van der Veer, Tasty Food Solutions

Options and applications

We understand that every application is different. Therefor our mixing tanks are configurable that way it will fit your product and process perfectly. Of course is a fully custom-made mixing tank also a possibility.

- MT50

- MT200

- MT500

- MT1000

- MT2500

- MT5000

- MT7500

- MT10000

- MT125000

- Other sizes are also possible

- Tiltable

- Integrated control panel

- Agitators

- Heated (Dimple, Halfpipe)

- Cooled (Dimple, Halfpipe)

- Loadcells

- Level Switches

- Cleaning connections

- Skid mounted

- Several finishing levels

- Several materials (304, 316L, Duplex)

- Gate agitator

- Anchor agitator

- Scraping agitator

- Propeller agitator

- Bottom driven agitator

- Dispersing disk

- Rotor/stator

- Screw agitator

- Combination of agitators

- High shear mixer

- Turbo mixer

- Side entry agitator

- Static mixer

- External homogenizer

Soups and sauces | Fruit | Food | ||

Tomato sauces | Fruitfilling | Mashed potato | ||

Sauces | Piefilling | Mechanically Deboned Meat | ||

Dressings | Fruitpuree | Ready-to-eat fillings | ||

Salsa | Jam | Egg | ||

Hummus | Marmelade | Jelly | ||

Soup | Fruitsauce | Peanut Butter | ||

Starch slurry | Applepulp | Pharma | ||

Spreads | Dairy | Lotions | ||

Confectionary | Milkconcentrate | Creams | ||

Fat cream | Cheese sauce | Wax | ||

Chocolate | Yoghurt | Toothpaste | ||

Caramel |

Standard mixing tanks or tailor made for your product and process

We understand that every mixing tank is different. Therefor we design our kettles tailormade for you, so you can be sure that the tank will suit to your product and process best. Options we can include into your tank are:

- Tiltable

- Fully integrated control panel

- Heated and/or cooled

- Agitators

- Loadcells

- Level switches

- Cleaning options

- Skid mounted

Agitator design and fabrication

In addition to tanks, Gpi De Gouwe also makes its own agitators. This way you have one point of contact for the entire tank concept. Agitators that we design and produce are:

- Gate agitator

- Anchor agitator

- Scraping agitator

- Propeller agitator

- Bottom driven agitator

- Dispersing disk

- Rotor/stator

- Screw agitator

- Combination of agitators

- High shear mixer

- Turbo mixer

- Side entry agitator

- Static mixer

- External homogenizer

Finishing levels

As a standard, Gpi ensures a high-finishing level. For some applications, such as in the food industry or even in the pharmaceutical industry, specific requirements are applicable. As a standard, food tanks are produced with an internal roughness of Ra 0.8, but if desired we can also produce tanks with much smoother (and therefore more hygienic) inner walls.

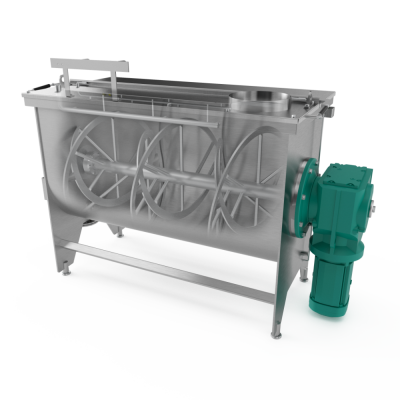

Ribbon Blender

Homogeneous mixing of solids

- Mixing times of 2 - 15 minutes per batch

- No product damage due to specially designed ribbon

- Mix both dry/dry and dry/wet

- Completely dead space free

Ribbon Blender

For blending and mixing dry substances, ribbon blenders are often used. Gpi supplies ribbon blenders for quick and homogeneous mixing of dry substances (sometimes dry/wet mixing). Our range of ribbon blenders starts at 100 liter and goes up to around 2000 liter.

A batch of dry substances is continuously mixes together by an inner and an outer ribbon, without any product damage. Depending on the product, the batch is homogeneously mixed in 2 to 15 minutes. In addition, it’s essential that there are no dead spaces.

Options and applications

The ribbon blenders are available in several sizes. Next to that we can offer different options.

Get in contact to hear all the possibilities.

- RB100 – 100 liter

- RB200 – 200 liter

- RB300 – 300 liter

- RB500 – 500 liter

- RB1000 – 1000 liter

- RB1500 – 1500 liter

- RB2000 – 2000 liter

- Various materials (SS304, SS316L)

- Heated and/or cooled

- Integrated control panel

- Manual or automated valves

- Loadcells

- CIP cleaning

- Lid equipped with removable grate

- Various seals

- Various surface finishes

- Granules

- Powders

- Rice

- Sugars

- Spices

- Flour

How a Ribbon Blender works

Two mixing ribbons

Through an inner and an outer ribbon, the batch product is continuously mixed together, without product damage. Depending on the product, the batch is mixed homogeneously in 2 to 15 minutes. In addition, it is essential that there are no dead spaces in the ribbon blender.

Configurable to your wishes

We understand that a standard ribbon blender does not always fit your requirements. Our ribbon blender can be equipped with a large number of options, so we can assure you that the ribbon blender fits your product and process best.

Some possible options:

- Various materials (SS304, SS316L)

- Heated and/or cooled

- Integrated control panel

- Manual or automated valves

- Loadcells

- CIP cleaning

- Lid equipped with removable grate

- Various seals

- Various surface finishes

Gallery