Batterline

A continuous batter preparation system

- Continuous high capacity batter production

- Fully automated for consistent results

- Low and high viscosity options

- Hygienic design

Batter Coating Preparation System

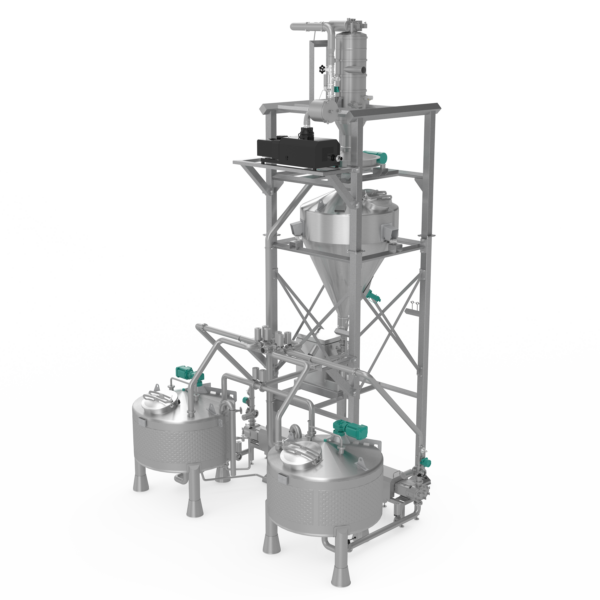

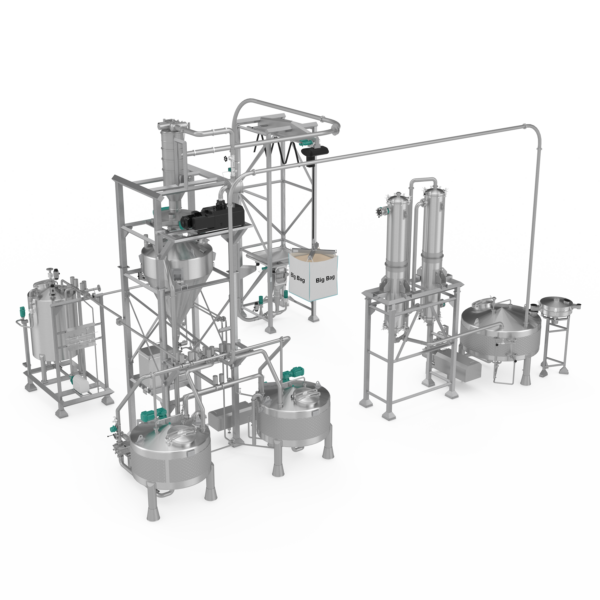

The Batterline is a system for high volume, continuous preparation of batter, as typically seen in the potato processing industry. The liquid batter is applied via an applicator, where product is covered in a thin layer before it is baked in the oven. This ‘battering’ or ‘coating’ is done to give the product certain additional properties, such as ‘bite’ (crispness), color or taste.

Mixing types and options

The Batterline has various options and mixing types.

Feel free to ask about all the possibilities.

Inline Mixer | High Speed Mixer | In Tank Mixer | |

Line Capacity Fryer | Up to 25.000kg/hr | Up to 25.000kg/hr | Up to 25.000kg/hr |

Capacity Coating System | Up to 5.000kg/hr | Up to 7.500kg/hr | Up to 7.000kg/hr |

Capacity Dry Matter | 75kg/min | 140kg/min | 100kg/min |

Dry Matter % | Up to 37-40% | Up to 48% | Up to 48% |

Viscosity | 500cP | 5.500cP | 5.500cP |

Type of Batters | Clearcoats | Clearcoats | Clearcoats |

|

| ||

Type of Products | French Fries | French Fries | French Fries |

|

|

- Cold water unit

- Falling film cooler

- Screw powder transport system

- Vacuum transport system

- Automation

- Manual bag unloading

- CIP cleaning system

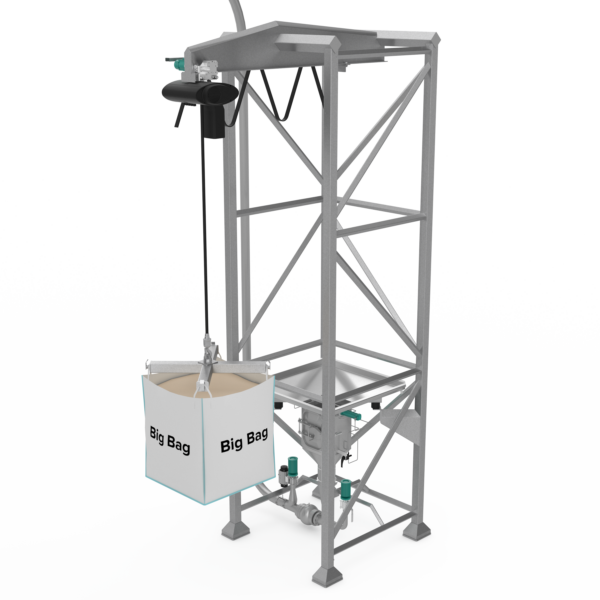

- Big Bag unloading stations

- Shell & tube or scraped surface heat exchanger (Kelstream)

- Potato

French Fries

Wedges

Specialties - Fish

- Meat

How a Batter Coating Preparation System works

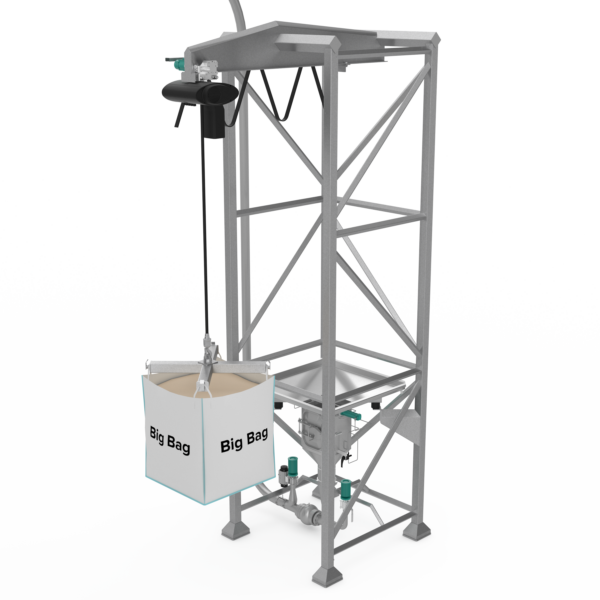

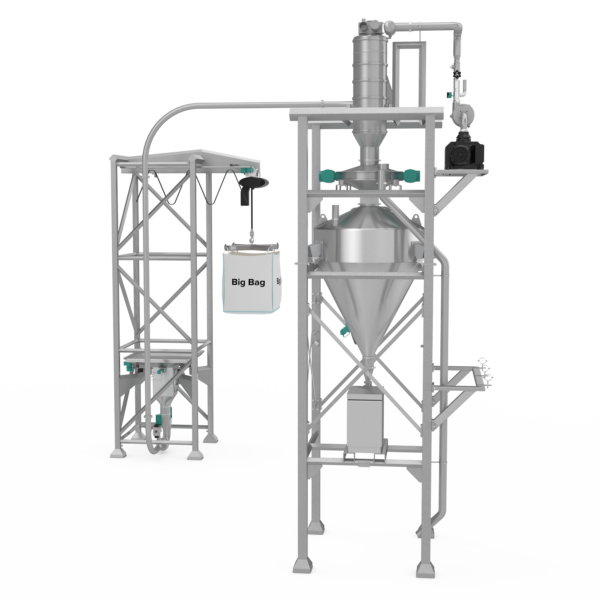

Powder handling

The first part of the Batterline is the powder handling part. The dry powder can be brought to the line in Big Bags or smaller bags. The powder is unloaded by a Big Bag station.

From that point, the powder can be transported by a transport screw or by vacuum. Working with vacuum transport allows you to keep the dry part of the line separated from the wet part.

The powder is transported to a powder hopper, where the second part of the line starts.

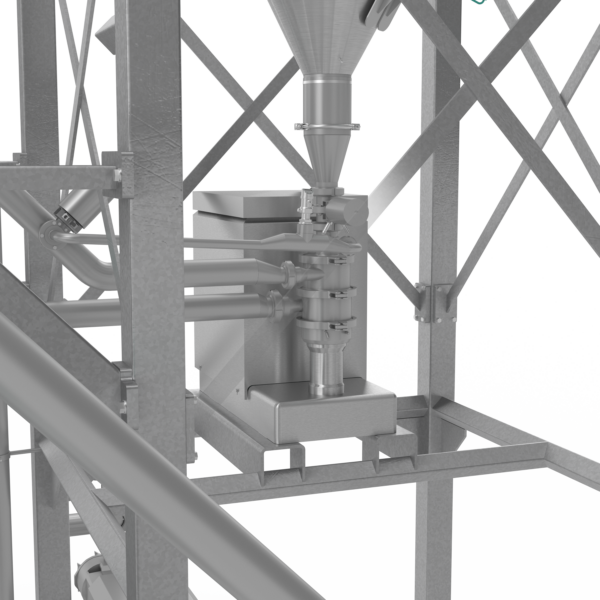

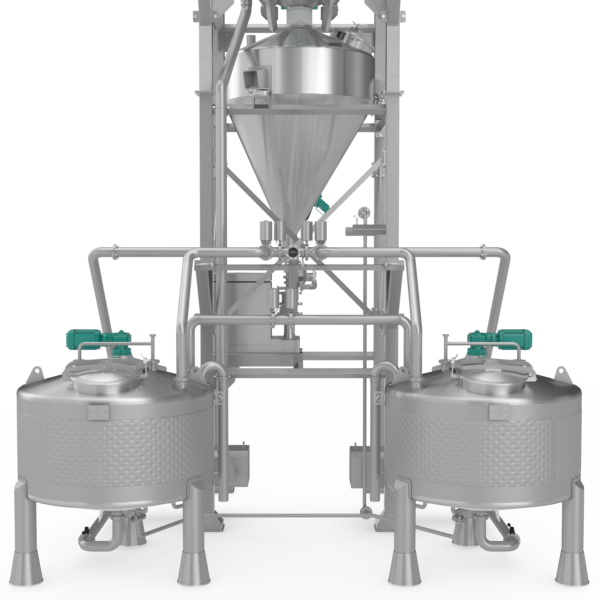

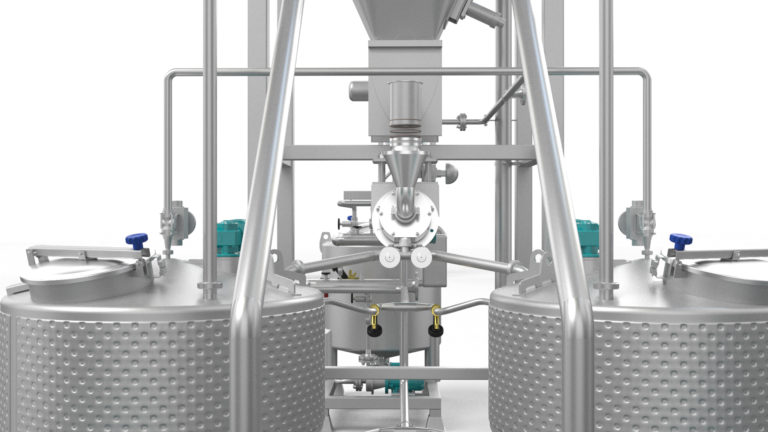

Batter preparation system

In the second part of the Batterline, the powder is mixed with water. A volumetric feeder doses the correct amount of powder into the mixing system, where it meets the correct water supply.

The batter is automatically mixed into the right ratio. The mixed batter goes to one of the buffer tanks where it can settle till ready. The batter mix alternately goes into one of the Buffer tanks, which gives a continuous flow of mixed batter.

Once the batter is settled, it is pumped to the working tank, part three.

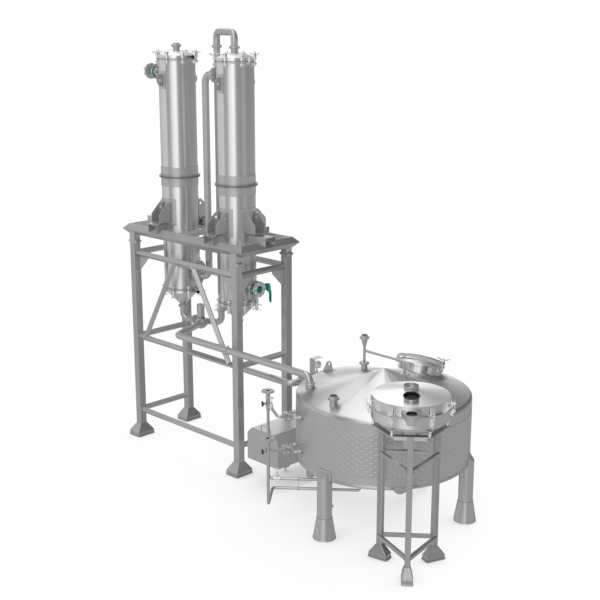

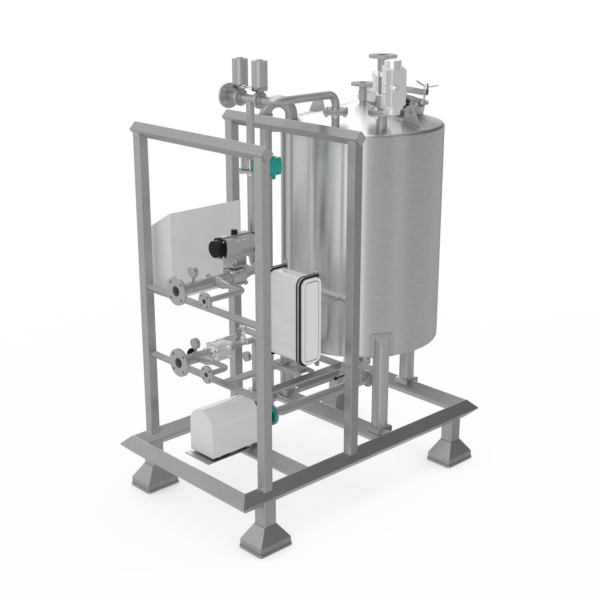

Batter return unit

The batter in the working tank, is pumped to the applicator. It passes one or more heat exchangers to guarantee the optimal temperature. The batter that is not left on the finished product runs back tot the working tank and passes a filter in the process. All particles that come along with the batter, such as pieces of French fries, are filtered out of the batter and disposed.

Gallery