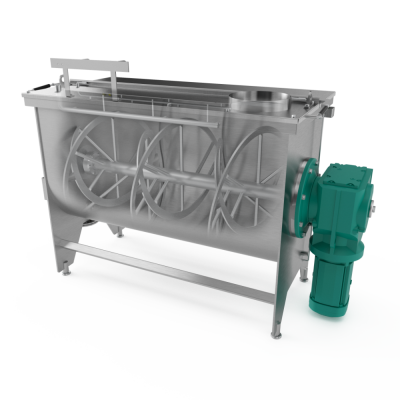

Ribbon Blender

Homogeneous mixing of solids

- Mixing times of 2 - 15 minutes per batch

- No product damage due to specially designed ribbon

- Mix both dry/dry and dry/wet

- Completely dead space free

Ribbon Blender

For blending and mixing dry substances, ribbon blenders are often used. Gpi supplies ribbon blenders for quick and homogeneous mixing of dry substances (sometimes dry/wet mixing). Our range of ribbon blenders starts at 100 liter and goes up to around 2000 liter.

A batch of dry substances is continuously mixes together by an inner and an outer ribbon, without any product damage. Depending on the product, the batch is homogeneously mixed in 2 to 15 minutes. In addition, it’s essential that there are no dead spaces.

Options and applications

The ribbon blenders are available in several sizes. Next to that we can offer different options.

Get in contact to hear all the possibilities.

- RB100 – 100 liter

- RB200 – 200 liter

- RB300 – 300 liter

- RB500 – 500 liter

- RB1000 – 1000 liter

- RB1500 – 1500 liter

- RB2000 – 2000 liter

- Various materials (SS304, SS316L)

- Heated and/or cooled

- Integrated control panel

- Manual or automated valves

- Loadcells

- CIP cleaning

- Lid equipped with removable grate

- Various seals

- Various surface finishes

- Granules

- Powders

- Rice

- Sugars

- Spices

- Flour

How a Ribbon Blender works

Two mixing ribbons

Through an inner and an outer ribbon, the batch product is continuously mixed together, without product damage. Depending on the product, the batch is mixed homogeneously in 2 to 15 minutes. In addition, it is essential that there are no dead spaces in the ribbon blender.

Configurable to your wishes

We understand that a standard ribbon blender does not always fit your requirements. Our ribbon blender can be equipped with a large number of options, so we can assure you that the ribbon blender fits your product and process best.

Some possible options:

- Various materials (SS304, SS316L)

- Heated and/or cooled

- Integrated control panel

- Manual or automated valves

- Loadcells

- CIP cleaning

- Lid equipped with removable grate

- Various seals

- Various surface finishes

Gallery