Batterline

A continuous batter preparation system

- Continuous high capacity batter production

- Fully automated for consistent results

- Low and high viscosity options

- Hygienic design

Batter Coating Preparation System

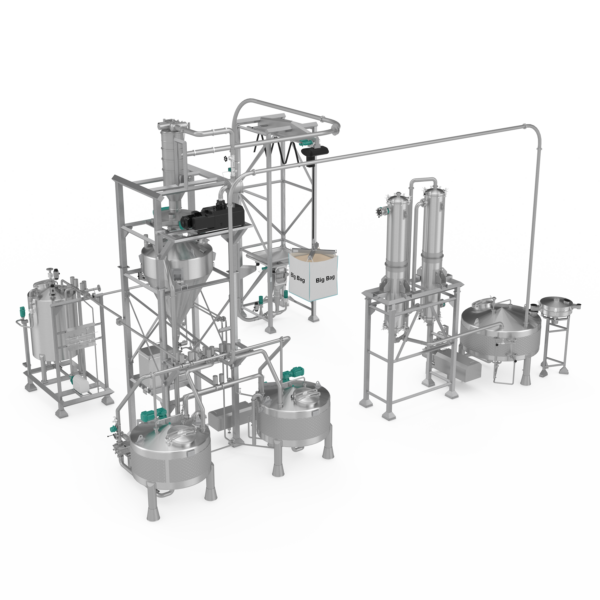

The Batterline is a system for high volume, continuous preparation of batter, as typically seen in the potato processing industry. The liquid batter is applied via an applicator, where product is covered in a thin layer before it is baked in the oven. This ‘battering’ or ‘coating’ is done to give the product certain additional properties, such as ‘bite’ (crispness), color or taste.

Mixing types and options

The Batterline has various options and mixing types.

Feel free to ask about all the possibilities.

Inline Mixer | High Speed Mixer | In Tank Mixer | |

Line Capacity Fryer | Up to 25.000kg/hr | Up to 25.000kg/hr | Up to 25.000kg/hr |

Capacity Coating System | Up to 5.000kg/hr | Up to 7.500kg/hr | Up to 7.000kg/hr |

Capacity Dry Matter | 75kg/min | 140kg/min | 100kg/min |

Dry Matter % | Up to 37-40% | Up to 48% | Up to 48% |

Viscosity | 500cP | 5.500cP | 5.500cP |

Type of Batters | Clearcoats | Clearcoats | Clearcoats |

|

| ||

Type of Products | French Fries | French Fries | French Fries |

|

|

- Cold water unit

- Falling film cooler

- Screw powder transport system

- Vacuum transport system

- Automation

- Manual bag unloading

- CIP cleaning system

- Big Bag unloading stations

- Shell & tube or scraped surface heat exchanger (Kelstream)

- Potato

French Fries

Wedges

Specialties - Fish

- Meat

How a Batter Coating Preparation System works

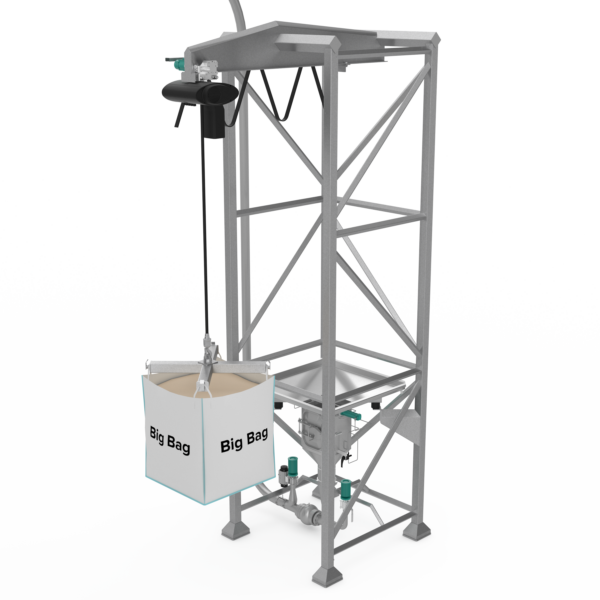

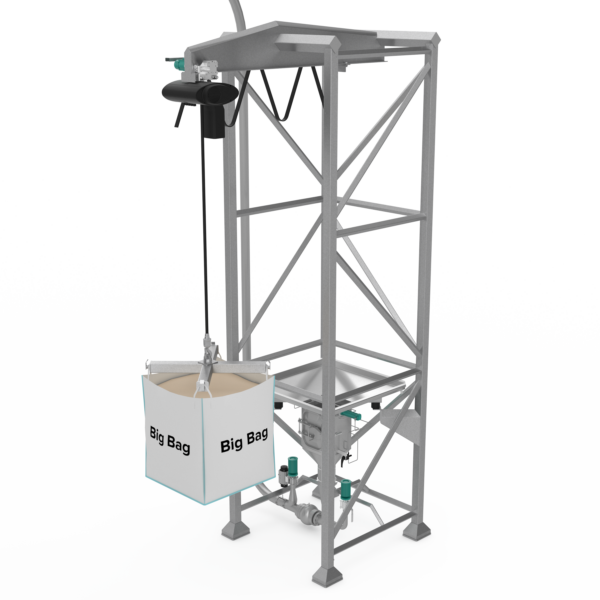

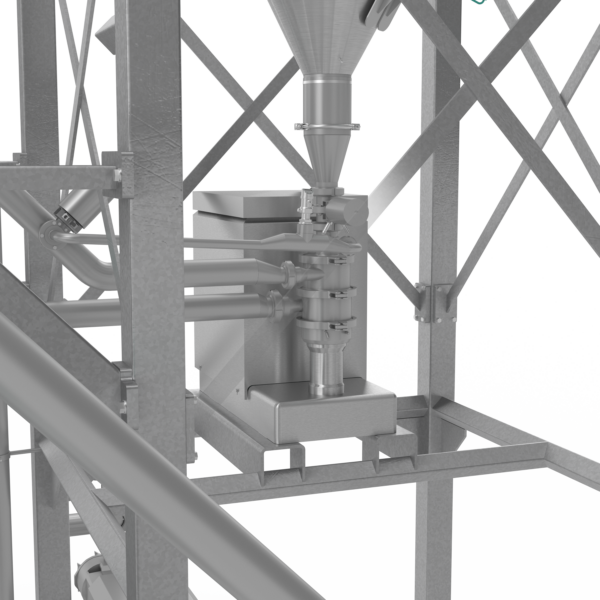

Powder handling

The first part of the Batterline is the powder handling part. The dry powder can be brought to the line in Big Bags or smaller bags. The powder is unloaded by a Big Bag station.

From that point, the powder can be transported by a transport screw or by vacuum. Working with vacuum transport allows you to keep the dry part of the line separated from the wet part.

The powder is transported to a powder hopper, where the second part of the line starts.

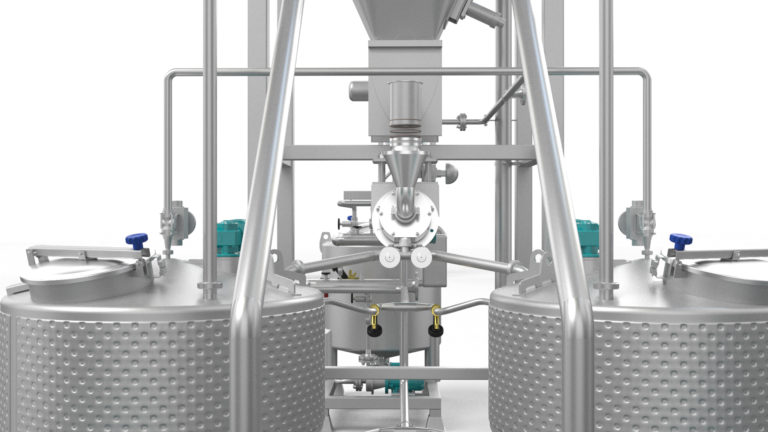

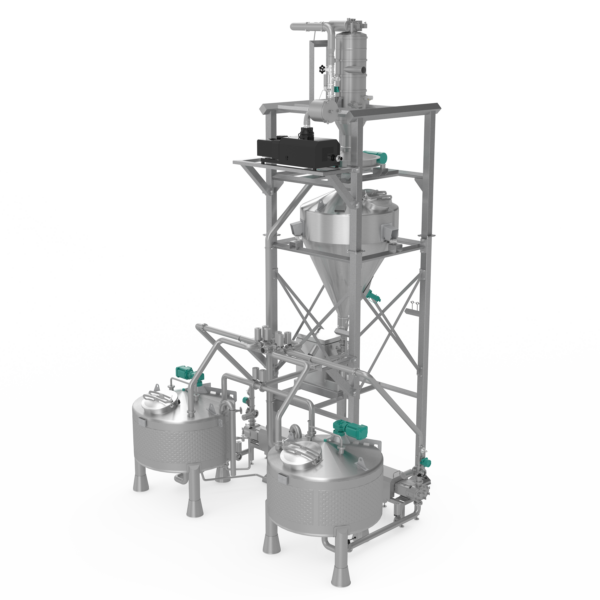

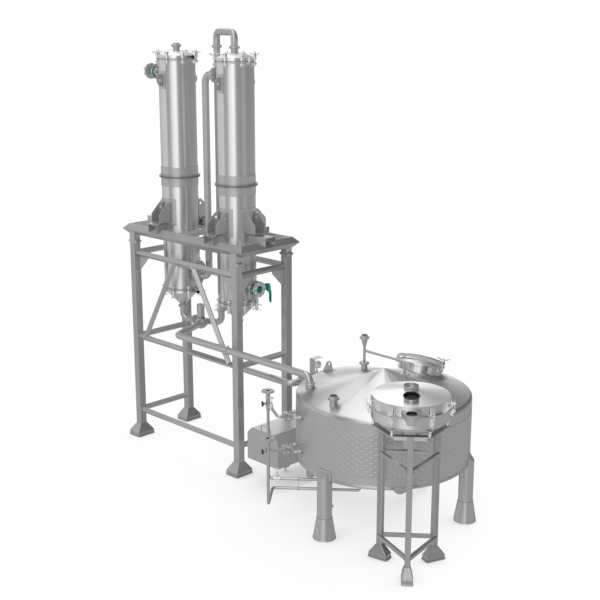

Batter preparation system

In the second part of the Batterline, the powder is mixed with water. A volumetric feeder doses the correct amount of powder into the mixing system, where it meets the correct water supply.

The batter is automatically mixed into the right ratio. The mixed batter goes to one of the buffer tanks where it can settle till ready. The batter mix alternately goes into one of the Buffer tanks, which gives a continuous flow of mixed batter.

Once the batter is settled, it is pumped to the working tank, part three.

Batter return unit

The batter in the working tank, is pumped to the applicator. It passes one or more heat exchangers to guarantee the optimal temperature. The batter that is not left on the finished product runs back tot the working tank and passes a filter in the process. All particles that come along with the batter, such as pieces of French fries, are filtered out of the batter and disposed.

Gallery

Skids

Your process compactly composed

- Seamless solution for your product and process

- Compact and plug-and-play solution

- Short installation time

- Guaranteed operation

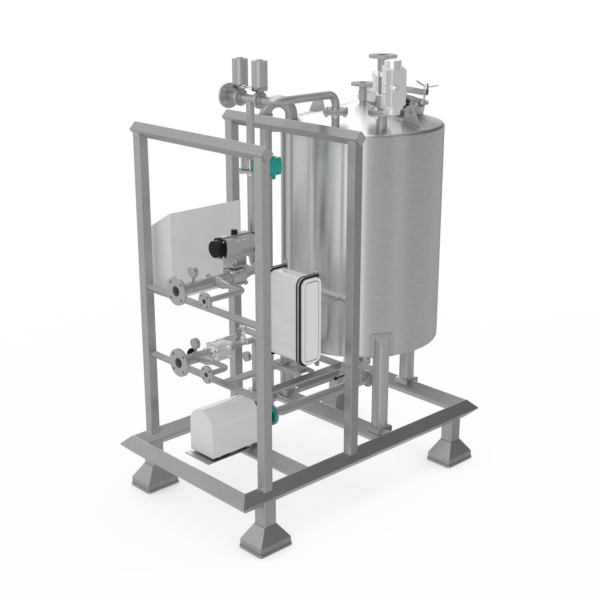

Stainless Steel Skid

Next to separate tanks and process equipment, Gpi designs and produces also integrated solutions on a frame, better known as skids. You can think of a preparation vessel in combination with a surface heat exhanger, control panel, the right valve train and piping.

Because Gpi designs the entire skid, you are assured that the technology supplied works seamlessly together and delivers the highest possible product and process quality.

The skid is supplied plug-and-play, so that you are hindered as little as possible in your production environment during installation.

Options and applications

Each application requires different requirements for the skid. That is why our skids are designed and manufactured in close cooperation between all our departments so that they perfectly match your product and process and meet all desired requirements.

- Integrated control panel

- Agitators

- Heated or cooled (Dimple, Halfpipe)

- Loadcells

- Level Switches

- Cleaning connections

- Warm- and cold water units

- Various finishing levels

- Various SS types possible (304, 316L)

- Pumps

- Piping and valves

Soups and sauces | Fruit | Food | ||

Tomato sauces | Fruitfilling | Mashed potato | ||

Sauces | Piefilling | Mechanically Deboned Meat | ||

Dressings | Fruitpuree | Ready-to-eat fillings | ||

Salsa | Jam | Egg | ||

Hummus | Marmelade | Jelly | ||

Soup | Fruitsauce | Peanut Butter | ||

Starch slurry | Applepulp | Pharma | ||

Spreads | Dairy | Lotions | ||

Confectionary | Milkconcentrate | Creams | ||

Fat cream | Cheese sauce | Wax | ||

Chocolate | Yoghurt | Toothpaste | ||

Caramel |

Pick the right configuration

We understand that every application is different. That is why we design our skids specifically to your specifications, so that we can be sure that the skid best suits your product and process.

Do you prefer certain brands in terms of component choice? Fine. Do you want us to choose the best components for you? No problem.

Gpi has good relationships with various component suppliers such as pumps, valves and instruments.

Finishing levels

Gpi uses a high level of quality as standard. We always design our skids with the highest possible level of hygiene.

We take into account the drain possibility, we avoid blind spots and our frames can be built in a so-called diamond frame, whereby the tubes are tilted. In this way, as little dirt as possible remains on your skid frame.

Additiveline

Mixing and dosing of additives for potato flakes

- The perfect solution for dosing additives to potato flakes

- Mixing and dosing of emulsifier, SAPP, dextrose, phosphate, colorants and more

- Single of multi tank systems

- Optional fully automated for consistent results

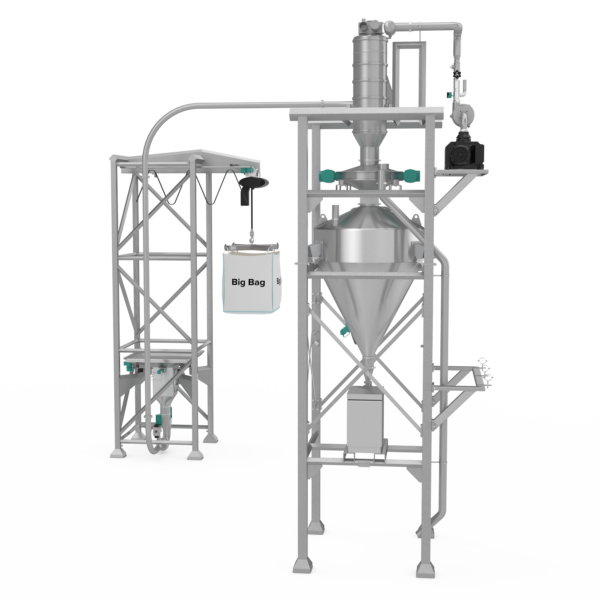

Additives mixing and dosing

The Additiveline is a system used in the potato industry for mixing and dosing additives in the potato flakes production line.

As potato production lines get bigger and bigger, the demand for automated systems increases.

Potatoes are cooked and mashed. The desired additives are added to the mashed potatoes. The puree is then pressed through large rollers into a thin layer, alse called film. This layer undergoes a rapid drying procedure until the desired humidity level is reached, after which this pressed layer is scraped off the drum. The layer is then broken up by a crusher into potato flakes of the desired size, which are then packed.

To give the flakes the desired characteristics in terms of flavour, color and other specifications, additives are dosed in the mashed potatoes. This includes product characteristics such as taste, a crispy ‘bite’ or a longer shelf life.

“Gpi De Gouwe is an enthusiastic club that stands for extensive knowledge

and effective, enjoyable collaboration“

Options, additives and products

An additive mixing and dosing system can have various setups and be provided with various options.

Contact us to find out what is possible.

- CIP Cleaning system

- Cold and/or warm water unit

- Screw powder transport system

- Vacuum transport system

- Big Bag Unloading

- Manual bag unloading

- Various mixing principles

- Dextrose

- Phosphate

- Emulsifier

- Sulfite

- Citric acid

- Pyrophosphate

- GMS

- SAPP

- Starch

- Potato flakes

- Snacks

- Chips

- Mashed potato

- Ready-to-eat meals

- Pasta & Gnocchi

- Potato specialties

- Soups and sauces

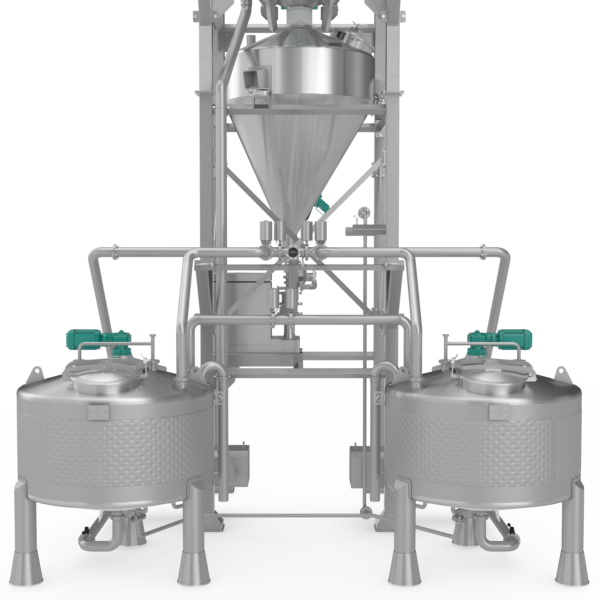

How an Additiveline works

Powder handling

The first part of the Additiveline is the powder handling part. The dry additives can be brought to the line in Big Bags by a Big Bag unloading station or in smaller bags through a powder filling cabinet. Of course, a combination of both is also possible.

From that point, the powder can be transported to the tanks by vacuum, screw conveyor or directly dosed in the tanks. Working with vacuum transport allows you to keep the dry part of the line separated from the wet part.

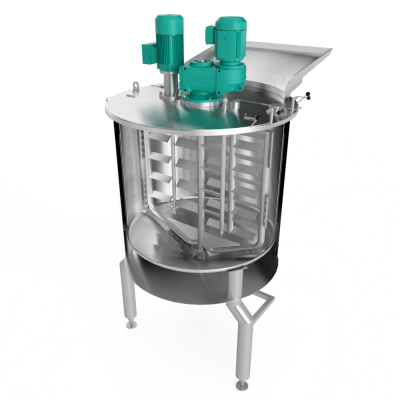

Mixing

In the second part of the Additiveline, the additives are mixed with water. A volumetric feeder doses the correct amount of additives to the water.

The solids percentage of additives and the characteristics of it, determine the agitator needed. This can be a simple propeller agitator, a disperser, a high speed mixer or even an inline mixer.

Several setups can be used. A single tank setup, where all additives are dosed into the same tank or a multiple tank setup, where certain additives have a dedicated mixing tank. The big advantage of the second option is that the additives can be dosed separately into the potato mash, which increase the flexibility of the system and the quality of the end product.

Dosing

Once the additives are mixed with water, they can be dosed in a ricer or the cooker. In a ricer only liquid additives can be dosed, where in the cooker it’s also possible to add dry additives.

Throughout the year, the potatoes used for making flakes will vary in quality and characteristics. By having the ability to change the dosing percentages, a nice and even quality can be produced whole year round.