Cooking Kettle

Food cooking

Perfect for your product and process.

- Fast heating and cooking of batches

- Inhouse knowledge of heating, mixing and blending

- Both manual as CIP cleaning possible

- Various options available for optimal integration on your product and proces

Cooking Kettle

Cooking kettles come in various sizes and can be used in a wide range of industries. Gpi Process Equipment is a manufacturer of stainless steel cooking kettles designed to fit your products and processes. Our cooking kettles start as small as 50 liter but can go up to 12.5m³.

For processes such as cooking and pasteurization, efficient heating of the tank is crucial and can be done various ways. Ensure the correct combination of heating capabilities and insulation of the tank in order to heat or cool your product within the desired time frame. Let us know directly what heating capacity you require, and we will collaborate with you in order to arrive at the most efficient solution, whether this concerns a dimple, a double wall or a half pipe.

“Gpi De Gouwe is a flexible partner, who listens carefully to the needs of the customer and delivers effective solutions without losing sight of the smaller client-specific aspects“

Wim van der Slot, Rimboe Sauzen

Options and applications

We understand that every application is different. Therefor our Cooking kettles are configurable that way it will fit your product and process perfectly. Of course is a fully custom-made Cooker also a possibility.

| CK250 | CK500 | CK1000 | CK1500 | CK2000 | CK3000 | |

| Working volume (L) | 250 | 500 | 1000 | 1500 | 2000 | 3000 |

| Cylindrical height (mm) | 600 | 800 | 1000 | 1200 | 1300 | 1500 |

| Diameter (mm) | 750 | 950 | 1200 | 1300 | 1400 | 1600 |

| Working height | 1450 | 1650 | 1850 | 2050 | 2150 | 2350 |

| Total height (incl. drive) | 2100 | 2400 | 2600 | 2800 | 2900 | 3100 |

| Outlet height | 500 | 500 | 500 | 500 | 500 | 500 |

| Heat transfer surface (m²) | 1,4 | 2,3 | 3,7 | 5,1 | 6,2 | 7,3 |

| Power drive (kW) | 1,1 | 1,5 | 2,2 | 3 | 3 | 4 |

| Cooking time at 3barg (average min.) | 25 | 31 | 39 | 43 | 47 | 60 |

| Maximum steam pressure (barg) | 4 | 4 | 4 | 4 | 4 | 4 |

| Steam consumption (kg/hr) | 90 | 150 | 230 | 320 | 390 | 450 |

- Tiltable

- Integrated control panel

- Agitators (see tab agitators)

- Heated (Dimple, Halfpipe)

- Loadcells

- Level Switches

- Cleaning connections

- Skid mounted

- Several finishing levels

- Several materials (304, 316L, Duplex)

- Gate agitator

- Anchor agitator

- Scraping agitator

- Propeller agitator

- Bottom driven agitator

- Dispersing disk

- Rotor/stator

- Screw agitator

- Combination of agitators

- High shear mixer

- Turbo mixer

- Side entry agitator

- Static mixer

- External homogenizer

Soups and sauces | Fruit | Food | ||

Tomato sauces | Fruitfilling | Mashed potato | ||

Sauces | Piefilling | Mechanically Deboned Meat | ||

Dressings | Fruitpuree | Ready-to-eat fillings | ||

Salsa | Jam | Egg | ||

Hummus | Marmelade | Jelly | ||

Soup | Fruitsauce | Peanut Butter | ||

Starch slurry | Applepulp | Pharma | ||

Spreads | Dairy | Lotions | ||

Confectionary | Milkconcentrate | Creams | ||

Fat cream | Cheese sauce | Wax | ||

Chocolate | Yoghurt | Toothpaste | ||

Caramel |

Standard cooking kettles or tailor made for your product and process

We understand that every cooking kettle is different. Therefor we design our kettles tailormade for you, so you can be sure that the tank will suit to your product and process best. Options we can include into your tank are:

- Tiltable

- Fully integrated control panel

- Agitators

- Loadcells

- Level switches

- Cleaning options

- Skid mounted

Agitator design and fabrication

In addition to tanks, Gpi De Gouwe also makes its own agitators. This way you have one point of contact for the entire tank concept. Agitators that we design and produce are:

- Anchor agitator

- Gate agitator

- Combination of agitators

- High shear mixers

- Turbo mixers

- Side entry agitators

- Static mixers

- External homogenizer

- Etc.

Finishing levels

As a standard, Gpi ensures a high-finishing level. For some applications, such as in the food industry or even in the pharmaceutical industry, specific requirements are applicable. As a standard, food tanks are produced with an internal roughness of Ra 0.8, but if desired we can also produce tanks with much smoother (and therefore more hygienic) inner walls.

Would you like to have more information about our Cooking kettles?

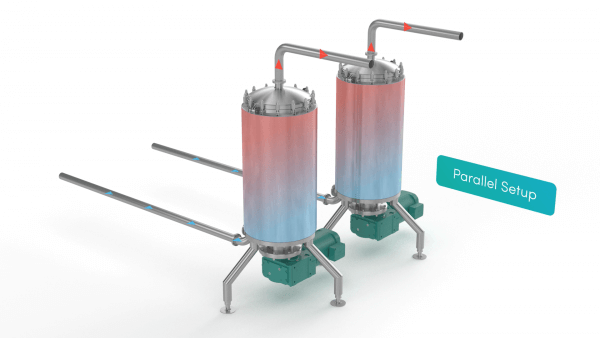

Kelstream

Inline heating or cooling of viscous products

- Complete surface is continuously scraped to prevent burn-on or product build-up

- Two heat transfer surfaces in one machine for highly efficient heat transfer

- Patented cartridge seal (lipseal of mechanical)

- Big heat transfer surface on a small footprint

Scraped Surface Heat Exchanger

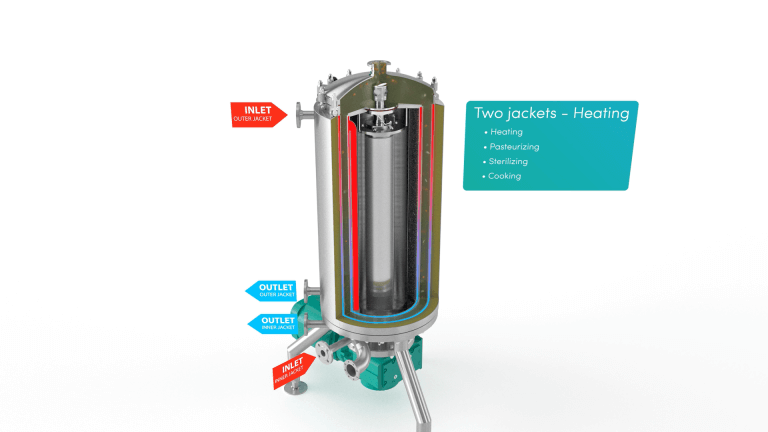

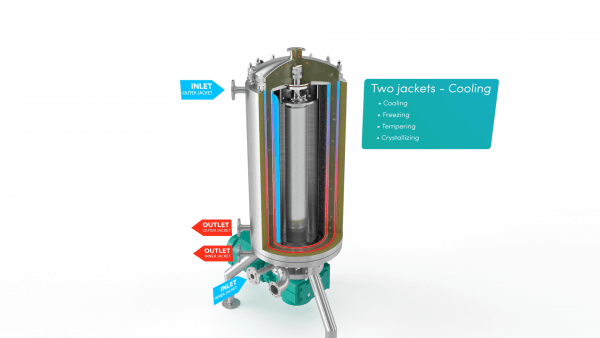

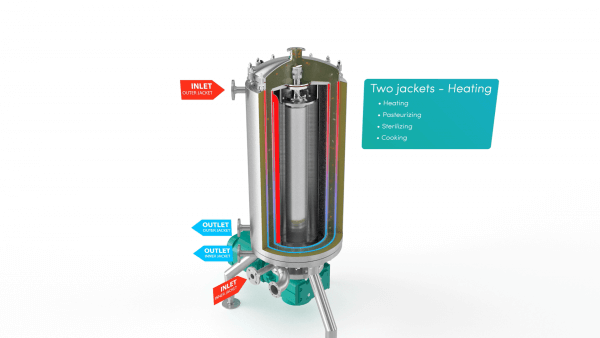

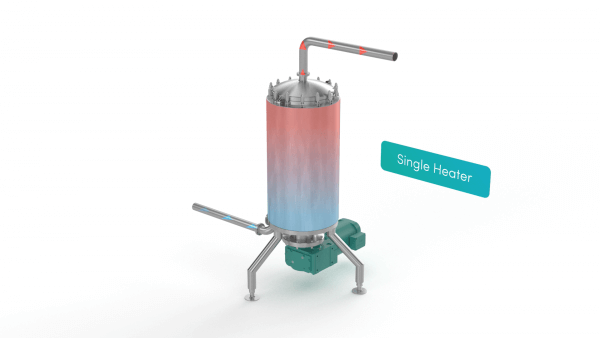

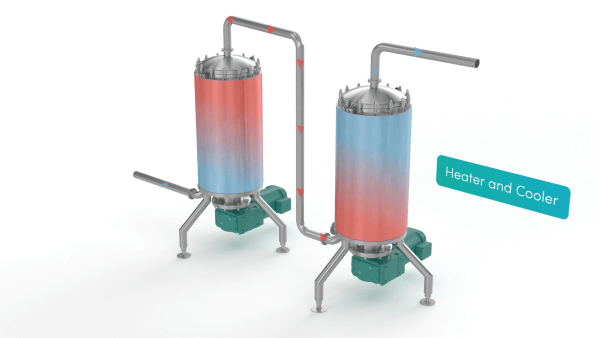

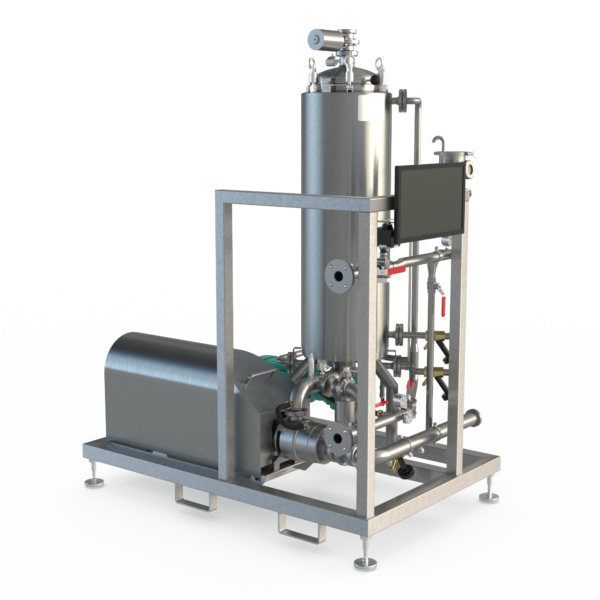

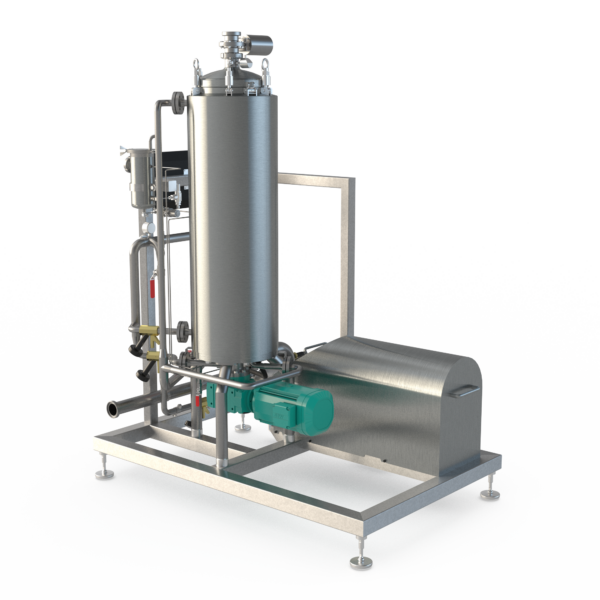

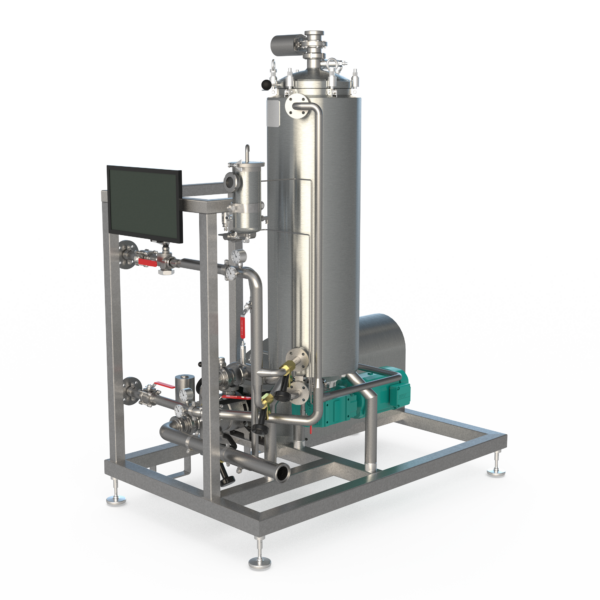

The Kelstream Scraped Surface Heat Exchanger is a vertical scraped heat exchanger with double concentric heated surfaces for an optimal heat exchange for food, feed, pharma and non-food.

This unique design in thermal processing brings all the benefits of different types heat exchangers together in one package: it can handle high viscous products like mashed potato, it has a large heated surface per unit, it takes only a small footprint and it doesn’t damage your product.

“Gpi De Gouwe is not only a highly innovative company to work with,

but they also help you select the perfect process equipment. “

Bas Jürgens, Protix

Models, options and products

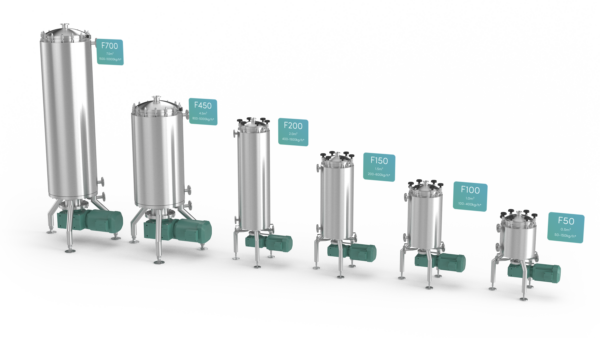

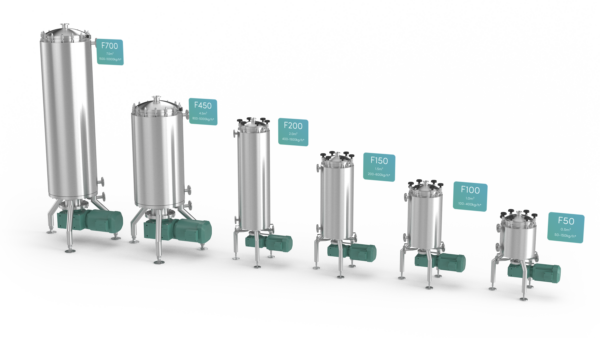

The Kelstream is available in several sizes. In addition, there are several options to choose from. The Kelstreams are available as single units and also fully integrated. Get in contact to hear all the possibilities.

Model | Heated surface | Lenght | Capacity | |||

Kelstream F50 | 0.5m² | 1250mm | 50-150kg/h | |||

Kelstream F100 | 1.0m² | 1550mm | 100-400kg/h | |||

Kelstream F150 | 1.5m² | 2050mm | 200-600kg/h | |||

Kelstream F200 | 2.0m² | 2400mm | 400-1500kg/h | |||

Kelstream F450 | 4.5m² | 2500mm | 800-5000kg/h | |||

Kelstream F700 | 7.0m² | 3200mm | 1500-10000kg/h |

- Patented cartridge seal (lipseal of mechanical)

- Double walled inlet and outlet

- Cover scraper

- Various connection types

- Motorcover

- Various plastics (Silicone, Viton, HNBR, PTFE, EPDM)

- Various materials (Duplex, SMO254, Hastelloy)

- Cooling

- Heating

- Tempering

- Crystallizing

- Pasteurizing

- Sterilizing

- Cooking

- Freezing

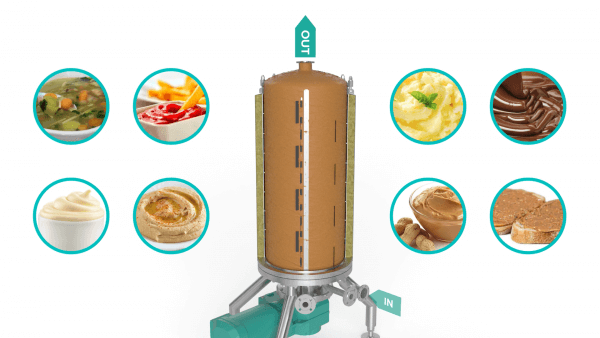

Soups and sauces | Fruit | Food | ||

Tomato sauces | Fruit filling | Mashed potato | ||

Sauces | Cake filling | Mechanically Deboned Meat | ||

Dressings | Fruit puree | Ready-to-eat fillings | ||

Salsa | Jam | Egg | ||

Hummus | Marmelade | Jelly | ||

Soup | Fruit sauce | Peanut Butter | ||

Starch slurry | Apple pulp | Pharma | ||

Spreads | Dairy | Lotions | ||

Confectionary | Milk concentrate | Creams | ||

Fat cream | Cheese sauce | Wax | ||

Chocolate | Yoghurt | Toothpaste | ||

Caramel |

How a Scraped Surface Heat Exchanger works

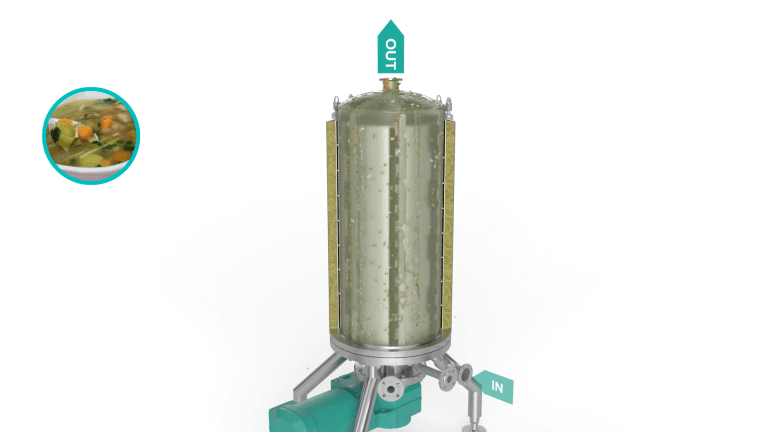

Continuously scraped

The Kelstream continuously scrapes the whole heated or cooled surface, resulting in an extremely efficient heattransfer. This scraping principle has a major efficiency advantage compared to conventional plate or tube-shaped heat exchangers. In addition the scrapers prevent product contamination on the wall.

Two heat transfer surfaces

The Kelstream has two heat transfer surfaces. The heating or cooling media is fully separated from the product area.

Media which can be used are: glycol, icewater, water, liquid ammonia, steam or hot water.

Heating or cooling products with solid components

With the Kelstream Scraped Surface Heat Exchanger you can cool and heat products that contain firm components, with a maximum size of 25mm. Product identity is preserved in this process.

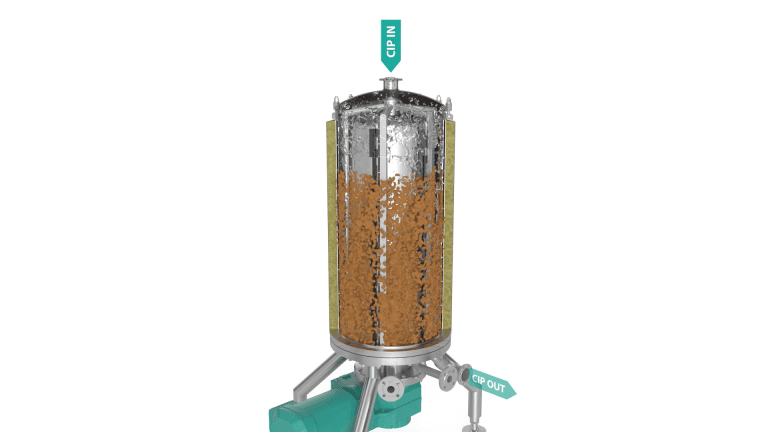

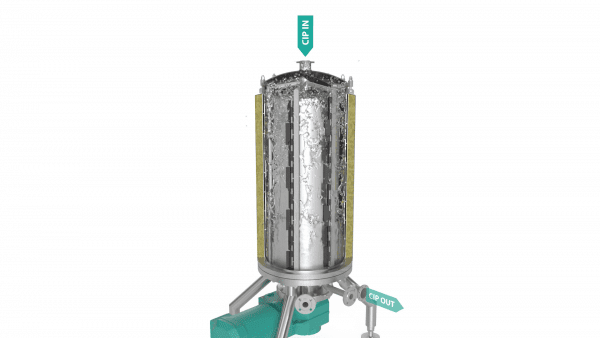

CIP cleanable

The Kelstream Scraped Surface Heat Exchanger can be fully included in the existing CIP system. You can clean the Kelstream counterlow, whereby the scraping system can rotate clockwise or anticlockwise. This results in optimum cleaning of the Kelstream.

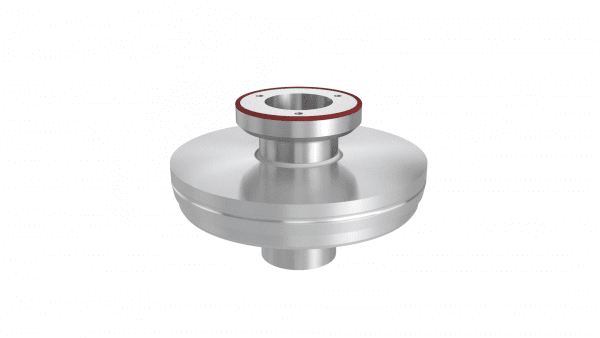

Patented cartridge seal

The Kelstream is equipped with a hygienic lipseal. This lipseal does not require a barrier fluid to function. When the product or process requires a different type of seal, there is also a choice of a single or double mechanical seal with various barrier fluids.

Gallery

![Kelstream3 [2021]](https://gpi-degouwe.com/wp-content/uploads/2021/03/Kelstream3-2021-600x600.png)

![Kelstream2 [2021]](https://gpi-degouwe.com/wp-content/uploads/2021/03/Kelstream2-2021-600x600.png)

![Kelstream1 [2021]](https://gpi-degouwe.com/wp-content/uploads/2021/03/Kelstream1-2021-600x600.png)

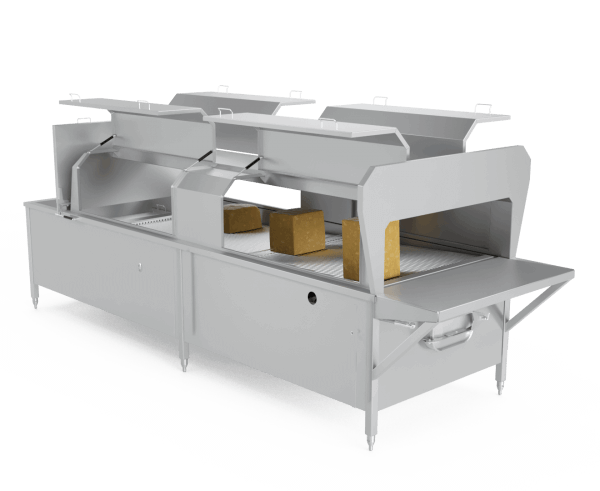

Melting Unit

For melting chocolate, fat and powders

- Continuous renewal of product

- Large heat transfer surface because of unique melting grid

- Both manual as CIP cleaning possible

- Melting capacity up to 6000kg/h per machine

Industrial Melting Unit

For inline- or batch melting of products, Gpi designs and produces industrial melting vats. The melting unit is capable to melt 100 up to 6000kg/h of various products. Think not only of chocolate, blocks of fat, margarine and butter, but also of powders and pellets.

The melting units range from 0.5m² up to 15m² of melting surface.

See the possible options and applications below.

“Gpi did a magnificent job of producing fast, efficient

and user-friendly melting tanks in line with our requirements“

Hans Zweers, Intersnack

Options and applications

The melting units are available in several sizes. Next to that we can offer different options.

Get in contact to hear all the possibilities.

- MU50 – 0.5m² melting surface

- MU100 – 1.0² melting surface

- MU150 – 1.5m² melting surface

- MU250 – 2.5m² melting surface

- MU350 – 3.5m² melting surface

- Including agitator to keep molten product homogeneous

- Integrated control panel

- Manual or automatic valves

- Load cells

- CIP cleaning

- Different types of folding lids

- Extra heating plates for optimally melted product

- Various types of stainless steel possible (304, 316L)

- Chocolate

- Fat

- Powders/sugars

- Butter/margarine

- Peanut butter

- Waxes

How a Melting Unit works

Unique melting grid design

Thanks to the special melting grid, manufactured on an automatic Tig/plasma welding bench, the product to be melted is constantly refreshed. In this way the temperature of the grid can be raised higher than on conventional melting units, without damaging (burning) delicate products. Due to the high heated surface, a high melting capacity is achieved on a minimal surface.

Customize to your wishes

We understand that a standard melting unit might not meet your wishes. That is why our melting trays can be equipped with a large number of options, so that we can be sure that the melting unit fits best with your product and process.

As an example, we can include an extra melting plate in the design to guarantee fully melted product for difficult products. In addition, the collection container for molten product can also be equipped with a heating jacket.

Test the melting unit

with your own product

Gpi has melting units available for testing with your own product. This ensures you get a melting unit that works.

Are you curious whether our melting unit is the right one for your product? Let us know so that we can convince you.