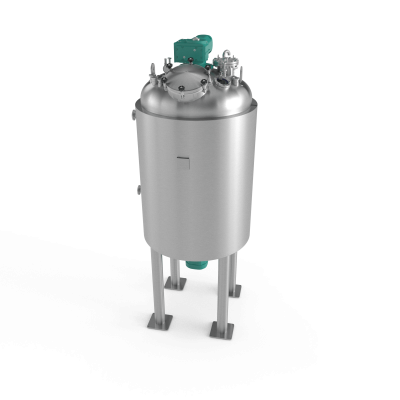

Chocolate Tank

Stainless Steel tanks especially for chocolate

- Homogeneous chocolate storage or processing

- Heating, cooling or tempering

- Inhouse design and production of agitators

- Sizes varying from 50 liters up to 50m³

Stainless Steel Chocolate Tanks

The production of good quality chocolate requires a very specific production process. Gpi designs and manufactures tanks and process equipment specifically intended for the processing of chocolate. The chocolate tanks meet the highest quality standards and hygiene standards.

With chocolate it is very important that the melting process is carefully controlled. Our tanks can be equipped with a double jacket in one or more segments to control the temperature of the chocolate.

“Gpi De Gouwe is a reliable partner, supplies quality and helps to shape

the desired process from start to finish“

Ad-Willem Slings and Laurens Bouwmeester, Menken Orlando

Options and applications

Each application requires different requirements from a tank. That is why our tanks are designed and manufactured in close cooperation between all our departments, so that they perfectly match your product and process and meet all desired quality requirements and quality marks.

- Tiltable

- Integrated control panel

- Agitators

- Heated (Dimple, Halfpipe, electric tracing or au-bain-marie)

- Loadcells

- Level Switches

- Tank placed on a frame

- Various finishing levels

- Various SS types possible (304, 316L)

- Integration of pumps, valves and piping

- Gate agitator

- Anchor agitator

- Scraping agitator

- Screw agitator

- Combination of agitators

“One factor that helped turn this challenging project into a tremendous success was the solid collaboration with Gpi“

Wouter van Durme, Project Manager at Puratos

Choose the correct configuration

The correct tank/agitator combination

Let us take care of the agitator in addition to the tank. Gpi De Gouwe has years of experience in designing and making agitators and agitator combinations that perfectly match your chocolate process. Think of anchor agitators, gate agitators with scrapers or other slowly rotating agitators.

Finishing level

As standard, we provide our food-grade tanks with an internal roughness of Ra 0.8, taking into account the latest requirements in the field of hygienic design.

Heating, cooling or keeping at temperature

Almost all tanks for chocolate have a double jacket, electric heating or a so-called au-bain-marie heating jacket.

We like to think along with you to guarantee the correct way of temperature control to store or process your chocolate in the highest possible quality.

Would you like to have more information about our Chocolate tanks?

Juice tanks

Hygienic tanks to buffer juices

- Atmospheric, pressurized and refrigerated storage

- Possibility of aseptic storage

- Combination with agitators for homogeneous storage

- Sizes varying from 5000 liter up to 200m³

Stainless Steel Tanks for drinks and juices

Whether you want to heat, cool, mix or store, Gpi has the best storage tanks for your juice processing.

There is an increasingly varied range of drinks on the shelf, with fresh juices, sports, energy and protein drinks becoming increasingly important. The processing of ingredients for these products requires specialist equipment, whereby the properties of the product must always be taken into account.

Options and applications

Each application requires different requirements from a juice tank. That is why our tanks are designed and manufactured in close cooperation between all our departments so that they perfectly match your product and process and meet all desired quality requirements and quality marks.

- Integrated control panel

- Agitators (see agitators page)

- Cooling (Dimple, Halfpipe)

- Loadcells

- Level Switches

- Integrated CIP

- Various finishing levels

- Various SS types possible (304, 316L)

- Integration of pumps, valves and piping

- U-Z agitator

- Gate agitator

- Anchor agitator

- Scraping agitator

- Propeller agitator

- Combination of agitators

- High shear mixer

- Side entry agitator

Choose the correct configuration

The correct tank/agitator combination

Let us take care of the agitator outside the tank. Gpi De Gouwe has years of experience in designing and making agitators and agitator combinations that perfectly match your juice processing process. A commonly used solution is the so-called U-Z agitator. This agitator maintains the homogeneity of the product, even if the product contains fiber or pulp.

Heating and cooling

When storing juices and drinks, it is essential that the product remains at the right temperature. Ensuring the correct combination of heating/cooling capacity and insulation on the tank, to heat or cool your product within the desired time.

Submit your cooling/heating case directly to Gpi with your application, we are happy to think along about the most efficient solution. Whether this is a dimple, double jacket or half pipe.

Hygenic and reliable

Gpi has a lot of experience in building tanks and equipment for fruit juices, spirits, dairy, beer or other drinks and concentrates. For example, we can give the right advice about heating or cooling the product, building pressurized tanks (PED / AD2000) to preserve freshness and thinking about the necessary finishing of the tank for hygienic purposes.

With in-house engineering, production and quality control, we maintain maximum control over quality and guarantee solutions that meet the strictest requirements in terms of hygiene, safety, durability and ease of operation. It goes without saying that we work within the set international standards and regulations, if desired we can also produce according to the EHEDG guidelines.

Aseptic storage

It is essential that no unwanted bacteria or contamination gets into the juices. For the most demanding applications, Gpi is able to design and manufacture aseptic, or sterile, storage tanks. Aseptic storage tanks are designed very hygienically, are often under pressure and are protected against unsolicited external influences.

Storage Tank

Standard or tailor made storage tanks. The perfect place to store your product.

- Hygienic tanks to store your product

- Used in food, pharma and cosmetics

- Both manual as CIP cleaning possible

- Various options available for optimal integration on your product and proces, such as heating/cooling and agitators.

Stainless Steel Storage Tank

Gpi De Gouwe produces all kinds of storage tanks in all sorts of sizes for all applications in the food, chocolate and cosmetics. This range spans high-quality finished 200 liter vessels for cosmetical or food products, to 25000 liter tanks for bulk storage of chocolates, ointments, creams and other products.

Even when it’s only storage, this doens’t mean that these tanks are only simply storage. We can also integrate heating, cooling and agitation on these tanks. For all options, please find the part below.

Lloyds audited Gpi, and accredited the company to independently design and manufacture pressure tanks over 0.5 bar (H + H1 certified). If your storage tank is part of a PED installation, the project engineer will closely collaborate with the client and our own QA/QC employee in order to carry out a risk analysis and set up a test & inspection plan. These tanks are usually designed to be in line with NEN-EN13445.

Bigger storage tanks? (>25000 liter)

Your supplier of stainless steel tanks, process tanks, storage tanks and pressure vessels from 25,000 liter.

Site built storage tanks

- Mehrere XL-Tanks vor Ort gebaut.

- Bis zu 30 Meter im Durchmesser und 30 Meter hoch.

Options and applications

We understand that every processline is different. Therefor our storage tanks are configurable that way it will fit your product and process perfectly. Of course is a fully custom-made storage tank also a possibility.

- Integrated control panel

- Agitators (see tab agitators)

- Heated (Dimple, Halfpipe)

- Cooled (Dimple, Halfpipe)

- Loadcells

- Level Switches

- Cleaning connections

- Skid mounted

- Several finishing levels

- Several materials (304, 316L, Duplex)

- Gate agitator

- Anchor agitator

- Scraping agitator

- Propeller agitator

- Bottom driven agitator

- Dispersing disk

- Rotor/stator

- Screw agitator

- Combination of agitators

- High shear mixer

- Turbo mixer

- Side entry agitator

- Static mixer

- External homogenizer

Soups and sauces | Fruit | Food | ||

Tomato sauces | Fruitfilling | Mashed potato | ||

Sauces | Piefilling | Mechanically Deboned Meat | ||

Dressings | Fruitpuree | Ready-to-eat fillings | ||

Salsa | Jam | Egg | ||

Hummus | Marmelade | Jelly | ||

Soup | Fruitsauce | Peanut Butter | ||

Starch slurry | Applepulp | Pharma | ||

Spreads | Dairy | Lotions | ||

Confectionary | Milkconcentrate | Creams | ||

Fat cream | Cheese sauce | Wax | ||

Chocolate | Yoghurt | Toothpaste | ||

Caramel |

Standard buffer tanks or tailor made for your product and process

We understand that every storage tank is different. Therefor we design our buffer tanks tailormade for you, so you can be sure that the tank will suit to your product and process best. Options we can include into your tank are:

Finishing levels

As a standard, Gpi ensures a high-finishing level. For some applications, such as in the food industry or even in the pharmaceutical industry, specific requirements are applicable. As a standard, food tanks are produced with an internal roughness of Ra 0.8, but if desired we can also produce tanks with much smoother (and therefore more hygienic) inner walls.

Buffer Tank

Standard or tailor made buffer tanks. Perfect for your product and process.

- Hygienic tanks to buffer your product in between processes

- Used in food, pharma and cosmetics

- Both manual as CIP cleaning possible

- Various options available for optimal integration on your product and proces, such as heating/cooling and agitators.

Stainless Steel Buffer Tank

Buffer tanks come in various sizes and can be used in a wide range of industries. Gpi Process Equipment is a manufacturer of stainless steel buffer tanks designed to fit your products and processes. Our buffer tanks start as small as 50 liter but can go up to 10.000 liter or even bigger.

Buffer tanks are ideal to have in between your processes, such as heating, cooling, filling and mixing. Let us know what you would like to achieve, and we will collaborate with you in order to arrive at the most efficient solution.

Options and applications

We understand that every processline is different. Therefor our buffer tanks are configurable that way it will fit your product and process perfectly. Of course is a fully custom-made Buffer tank also a possibility.

- BT50

- BT100

- BT150

- BT200

- BT300

- BT400

- BT500

- BT600

- BT800

- BT1000

- BT1500

- Other sizes are also possible

- Tiltable

- Integrated control panel

- Agitators

- Heated (Dimple, Halfpipe)

- Cooled (Dimple, Halfpipe)

- Loadcells

- Level Switches

- Cleaning connections

- Skid mounted

- Several finishing levels

- Several materials (304, 316L, Duplex)

- Gate agitator

- Anchor agitator

- Scraping agitator

- Propeller agitator

- Bottom driven agitator

- Dispersing disk

- Rotor/stator

- Screw agitator

- Combination of agitators

- High shear mixer

- Turbo mixer

- Side entry agitator

- Static mixer

- External homogenizer

Soups and sauces | Fruit | Food | ||

Tomato sauces | Fruitfilling | Mashed potato | ||

Sauces | Piefilling | Mechanically Deboned Meat | ||

Dressings | Fruitpuree | Ready-to-eat fillings | ||

Salsa | Jam | Egg | ||

Hummus | Marmelade | Jelly | ||

Soup | Fruitsauce | Peanut Butter | ||

Starch slurry | Applepulp | Pharma | ||

Spreads | Dairy | Lotions | ||

Confectionary | Milkconcentrate | Creams | ||

Fat cream | Cheese sauce | Wax | ||

Chocolate | Yoghurt | Toothpaste | ||

Caramel |

Standard buffer tanks or tailor made for your product and process

We understand that every buffer tank is different. Therefor we design our buffer tanks tailormade for you, so you can be sure that the tank will suit to your product and process best. Options we can include into your tank are:

Finishing levels

As a standard, Gpi ensures a high-finishing level. For some applications, such as in the food industry or even in the pharmaceutical industry, specific requirements are applicable. As a standard, food tanks are produced with an internal roughness of Ra 0.8, but if desired we can also produce tanks with much smoother (and therefore more hygienic) inner walls.