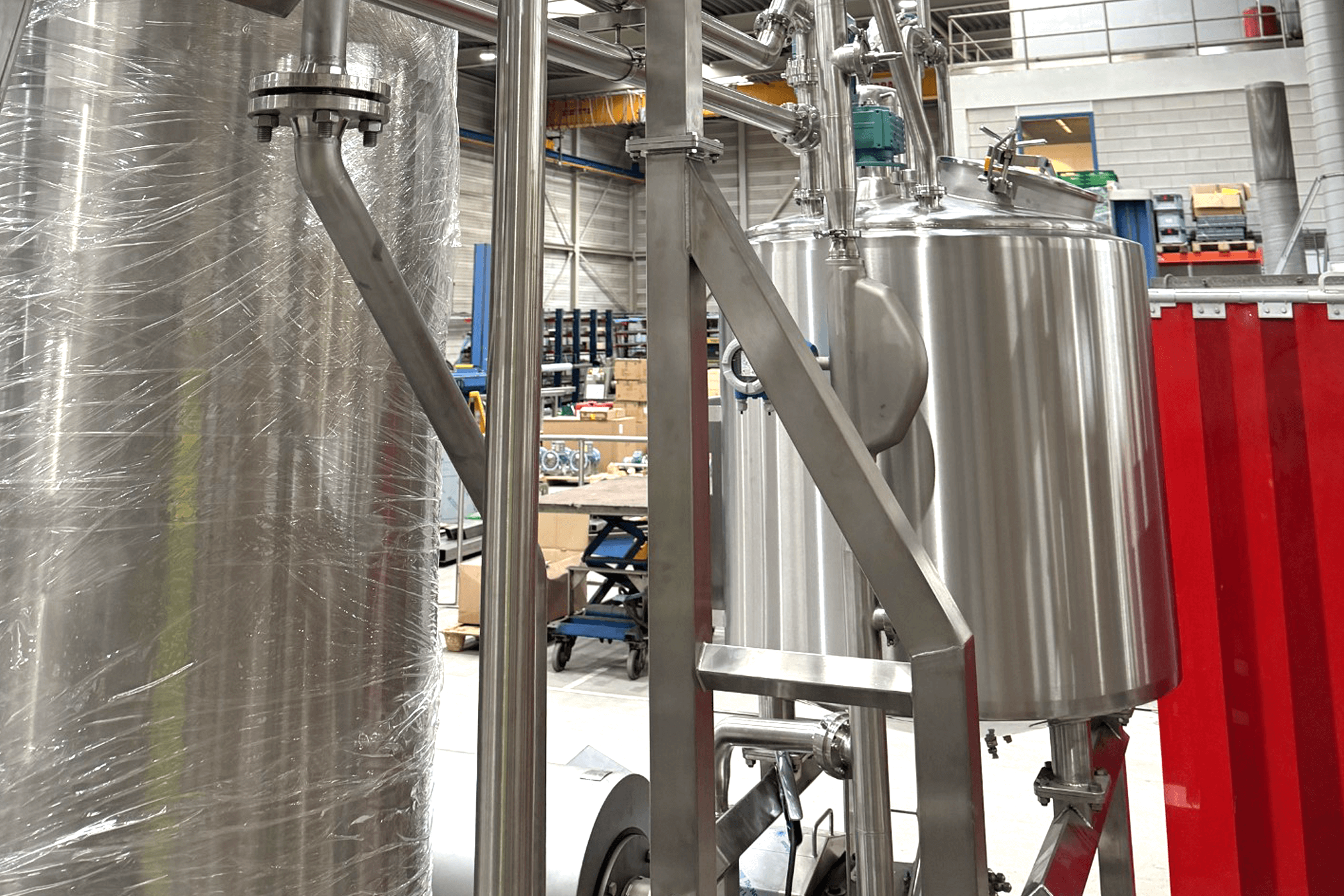

At Gpi in Gouda, our team is currently working intensively on a high-capacity red sauce processing line for one of the leading manufacturers and distributors of fast-moving consumer goods in the Caribbean region.

The line has an output of over 4,000kg of sauce per hour and consists of a wide range of components, including three Kelstream scraped surface heat exchangers, mixing, holding and balancing tanks, an inline dispersing machine, pumps and piping. In addition, the line is equipped with various measuring instruments and control components to ensure a fully controlled and reliable process. The entire installation is CIP-cleanable, which is also supplied by Gpi.

The skid-mounted design, with stairs and working platform, allows operators to safely add additional ingredients during the process. We deliver the complete turnkey solution, including automation, installation and commissioning, fully unburdening our customer throughout the project.

Process flow

The sauce is produced through a continuous and controlled process, with efficiency and product quality as key priorities.

The process starts with cold preparation, during which powders and liquids are accurately mixed using an inline dispersing machine. From this stage, the product is transferred to a buffer tank, ensuring a stable and consistent product flow throughout the subsequent process steps.

From the buffer tank, the sauce is pumped through a Kelstream scraped surface heat exchanger, where it is rapidly and precisely heated to pasteurisation temperature. Immediately after heating, the sauce enters the holding section, where the temperature is carefully maintained for a variable pasteurisation time, depending on the product type.

After the holding phase, the sauce passes through a balancing tank, which ensures a continuous process and guarantees a uniform feed to the cooling stages at all times. This keeps the production process stable and reliable. The sauce is then cooled in a two-stage cooling process using Kelstreams to reach the required temperature, after which it is ready for the filling line.

This process concept combines flexibility with process reliability and is designed for the efficient, continuous production of high-quality sauces.

Gpi is a reliable partner in custom-made process systems for the food industry. Our equipment is designed for a wide range of applications, including sauces and condiments, ready meals, soups, chocolate and confectionery, fruit and spreads.

Ready to optimize your process? We would be happy to discuss the possibilities!